Cleaning Your MAP Sensor: Beyond Commercial Cleaners

Related Articles: Cleaning Your MAP Sensor: Beyond Commercial Cleaners

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Cleaning Your MAP Sensor: Beyond Commercial Cleaners. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

- 1 Related Articles: Cleaning Your MAP Sensor: Beyond Commercial Cleaners

- 2 Introduction

- 3 Cleaning Your MAP Sensor: Beyond Commercial Cleaners

- 3.1 The Importance of a Clean MAP Sensor

- 3.2 Understanding the Cause of MAP Sensor Contamination

- 3.3 Exploring Alternative Cleaning Methods

- 3.4 FAQs on MAP Sensor Cleaning Alternatives

- 3.5 Tips for Cleaning Your MAP Sensor

- 3.6 Conclusion

- 4 Closure

Cleaning Your MAP Sensor: Beyond Commercial Cleaners

The manifold absolute pressure (MAP) sensor plays a crucial role in a vehicle’s engine management system. It measures the pressure inside the intake manifold, providing the engine control unit (ECU) with vital data for determining fuel injection and ignition timing. Over time, the MAP sensor can become contaminated with dirt, oil, and other deposits, hindering its performance and leading to engine misfires, poor fuel economy, and even engine damage. While commercial MAP sensor cleaners offer a convenient solution, understanding the underlying principles and exploring alternative cleaning methods can provide valuable insights into maintaining this essential component.

The Importance of a Clean MAP Sensor

A clean MAP sensor ensures accurate pressure readings, enabling the ECU to precisely control fuel injection and ignition timing. This optimizes engine performance, leading to:

- Improved Fuel Economy: Precise fuel delivery reduces unnecessary fuel consumption.

- Reduced Emissions: Optimal combustion minimizes harmful pollutants.

- Enhanced Engine Performance: Smooth engine operation with increased power output.

- Prevents Engine Damage: Accurate readings prevent misfires and other issues that can damage engine components.

Understanding the Cause of MAP Sensor Contamination

The MAP sensor, typically located on the intake manifold, is exposed to a harsh environment. Dust, oil vapors, and other contaminants can accumulate on the sensor’s sensitive diaphragm and sensing element, hindering its ability to accurately measure pressure. This contamination can arise from:

- Engine Blow-by: Gases escaping from the engine’s crankcase can enter the intake manifold, carrying oil and other contaminants.

- Air Filter Failure: A dirty or damaged air filter allows dust and debris to enter the intake manifold.

- Fuel System Issues: Leaking injectors or fuel lines can deposit fuel residue on the MAP sensor.

- Environmental Factors: Road dust, pollen, and other airborne particles can accumulate on the sensor.

Exploring Alternative Cleaning Methods

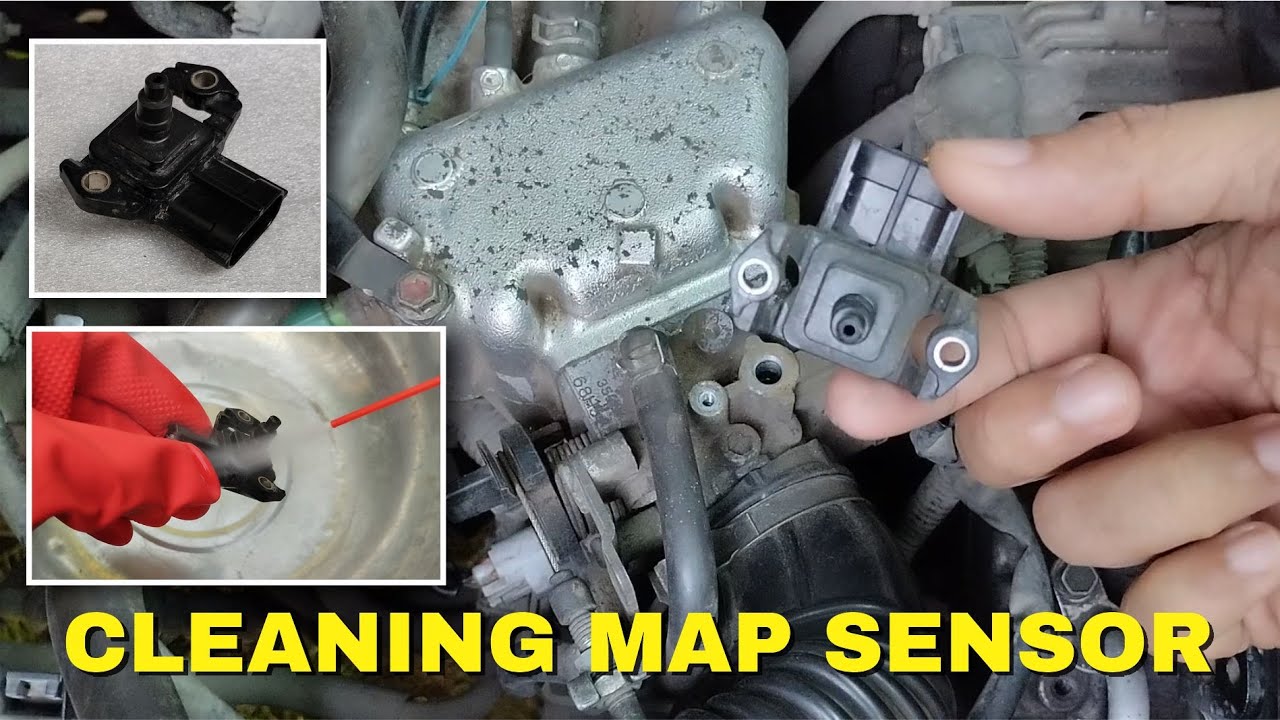

While commercial MAP sensor cleaners are readily available, alternative methods offer cost-effective and environmentally friendly solutions. These methods involve carefully removing the MAP sensor and cleaning its critical components:

1. Compressed Air and a Soft Brush:

- Method: Gently blow compressed air into the sensor’s openings to dislodge loose debris. Use a soft-bristled brush to carefully clean the sensor’s surface, avoiding any pressure that could damage the diaphragm.

- Benefits: Simple, inexpensive, and effective for removing loose dirt and debris.

- Considerations: May not be sufficient for removing stubborn oil or fuel deposits.

2. Isopropyl Alcohol and a Q-Tip:

- Method: Dip a Q-tip into isopropyl alcohol (99% concentration) and gently clean the sensor’s diaphragm and sensing element. Avoid excessive pressure and ensure the alcohol dries completely before reassembling the sensor.

- Benefits: Effective for removing oil and fuel deposits, readily available, and relatively inexpensive.

- Considerations: Excessive alcohol application can damage the sensor’s diaphragm, and improper drying can lead to corrosion.

3. Electronic Contact Cleaner:

- Method: Apply a small amount of electronic contact cleaner to a clean cloth and gently wipe the sensor’s diaphragm and sensing element. Allow the cleaner to evaporate completely before reassembling the sensor.

- Benefits: Effectively removes oil, grease, and other contaminants while leaving no residue.

- Considerations: Ensure the cleaner is compatible with the sensor’s materials and avoid contact with sensitive electronic components.

4. Cleaning with a Vacuum:

- Method: Use a vacuum cleaner with a soft brush attachment to gently remove dust and debris from the sensor’s openings. Avoid excessive suction that could damage the diaphragm.

- Benefits: Effective for removing loose debris and can be used in conjunction with other cleaning methods.

- Considerations: Requires a vacuum cleaner with a suitable attachment and careful handling to avoid damaging the sensor.

FAQs on MAP Sensor Cleaning Alternatives

1. How often should I clean my MAP sensor?

The frequency of cleaning depends on driving conditions and environmental factors. As a general rule, cleaning every 30,000 to 50,000 miles or when noticeable engine performance issues arise is recommended.

2. Can I use WD-40 to clean my MAP sensor?

WD-40 is not recommended for cleaning MAP sensors. It contains lubricants that can leave residue and hinder the sensor’s operation.

3. Is it safe to use compressed air to clean the MAP sensor?

Using compressed air is generally safe, but ensure the air pressure is low and directed away from the sensor’s diaphragm to avoid damage.

4. What if I accidentally damage the MAP sensor during cleaning?

If the sensor is damaged, it needs to be replaced. Avoid applying excessive force or using harsh chemicals that can harm the delicate components.

5. Can I clean the MAP sensor without removing it?

Cleaning the sensor without removing it is not recommended. Accessing the sensor’s critical components for thorough cleaning requires removal.

Tips for Cleaning Your MAP Sensor

- Always disconnect the battery before working on the MAP sensor.

- Use a clean, dry workspace to prevent contamination.

- Avoid using excessive force or harsh chemicals that can damage the sensor.

- Ensure the sensor is completely dry before reassembling it.

- After cleaning, test drive the vehicle to confirm improved performance.

Conclusion

Maintaining a clean MAP sensor is crucial for optimal engine performance, fuel economy, and emissions control. While commercial cleaners offer a convenient solution, alternative cleaning methods using compressed air, isopropyl alcohol, electronic contact cleaner, and even a vacuum cleaner provide cost-effective and environmentally friendly options. Understanding the underlying principles and following proper cleaning techniques ensures the longevity and accurate operation of this vital engine component. Remember to prioritize safety and avoid using harsh chemicals or excessive force that could damage the sensor. By adopting a proactive approach to MAP sensor cleaning, drivers can ensure their vehicles run smoothly and efficiently for years to come.

Closure

Thus, we hope this article has provided valuable insights into Cleaning Your MAP Sensor: Beyond Commercial Cleaners. We hope you find this article informative and beneficial. See you in our next article!