The Crucial Role of the Manifold Absolute Pressure Sensor in Engine Performance

Related Articles: The Crucial Role of the Manifold Absolute Pressure Sensor in Engine Performance

Introduction

With great pleasure, we will explore the intriguing topic related to The Crucial Role of the Manifold Absolute Pressure Sensor in Engine Performance. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Crucial Role of the Manifold Absolute Pressure Sensor in Engine Performance

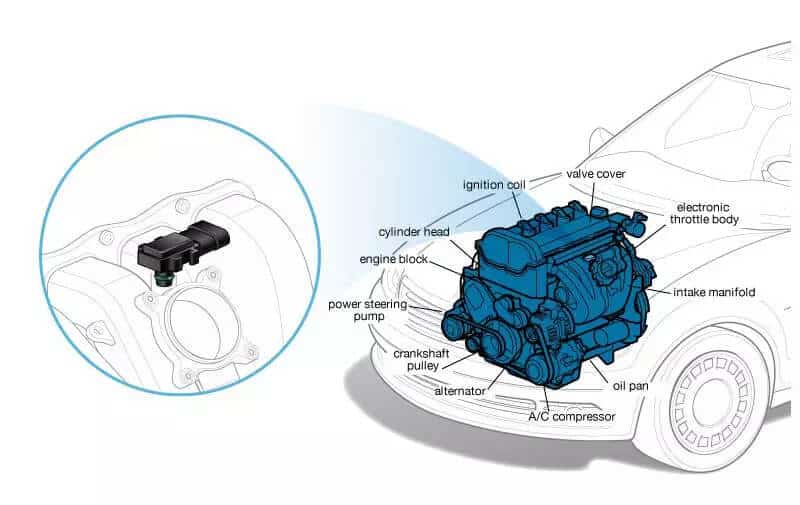

The manifold absolute pressure sensor (MAP sensor), often referred to as the "MAP sensor," is an integral component in modern internal combustion engines. It plays a critical role in regulating fuel delivery and ignition timing, ultimately influencing engine performance, fuel efficiency, and emissions. Understanding the operation and importance of the MAP sensor is essential for both automotive enthusiasts and professionals seeking to optimize engine performance and ensure reliable operation.

Understanding the MAP Sensor’s Function

The MAP sensor’s primary function is to measure the absolute pressure within the engine’s intake manifold. This pressure, often referred to as manifold vacuum, reflects the amount of air drawn into the cylinders during the intake stroke. The MAP sensor converts this pressure information into an electrical signal that the engine control unit (ECU) can interpret.

How the MAP Sensor Works

The MAP sensor operates on the principle of piezoresistive technology. It comprises a small, pressure-sensitive semiconductor device that changes its electrical resistance based on the pressure applied. When air enters the intake manifold, the pressure acts upon the sensor’s diaphragm, causing it to deform. This deformation alters the resistance of the semiconductor, resulting in a change in the electrical signal output.

The ECU uses this signal to determine the amount of air entering the engine. This information is crucial for calculating the appropriate amount of fuel to inject and the optimal timing for ignition. By precisely controlling these parameters, the ECU ensures efficient combustion and optimal engine performance.

The Importance of the MAP Sensor

The MAP sensor’s importance in engine operation cannot be overstated. It plays a crucial role in:

- Fuel Delivery: The ECU utilizes the MAP sensor reading to calculate the amount of fuel required for optimal combustion. An inaccurate MAP sensor reading can lead to either a lean or rich fuel mixture, affecting fuel efficiency and engine performance. A lean mixture can result in engine knocking or damage, while a rich mixture leads to increased emissions and reduced fuel economy.

- Ignition Timing: The MAP sensor reading is also used to determine the optimal spark timing. The ECU adjusts ignition timing based on the manifold pressure, ensuring efficient combustion and maximizing power output. An inaccurate MAP sensor reading can result in suboptimal ignition timing, affecting engine performance and fuel efficiency.

- Emissions Control: The MAP sensor plays a critical role in emissions control systems. By providing the ECU with accurate information about the amount of air entering the engine, it enables the ECU to adjust the air-fuel ratio to minimize harmful emissions.

- Engine Performance: An accurate MAP sensor reading is essential for achieving optimal engine performance. It allows the ECU to precisely control fuel delivery and ignition timing, resulting in smooth operation, efficient power delivery, and optimal fuel economy.

Signs of a Faulty MAP Sensor

A malfunctioning MAP sensor can significantly impact engine performance. Common symptoms of a faulty MAP sensor include:

- Poor Engine Performance: The engine may experience hesitation, rough idling, or a loss of power.

- Increased Fuel Consumption: A faulty MAP sensor can lead to an inaccurate fuel-air mixture, resulting in increased fuel consumption.

- Check Engine Light: A malfunctioning MAP sensor will typically trigger the check engine light, accompanied by a diagnostic trouble code (DTC) related to the MAP sensor.

- Emissions Problems: An inaccurate MAP sensor reading can disrupt the emissions control system, leading to increased emissions.

- Engine Knocking: A faulty MAP sensor can lead to a lean fuel mixture, resulting in engine knocking or pinging.

Diagnosing and Replacing a Faulty MAP Sensor

Diagnosing a faulty MAP sensor involves a combination of visual inspection, diagnostic tools, and testing procedures:

- Visual Inspection: Inspect the MAP sensor for any visible damage, such as cracks, leaks, or corrosion.

- Diagnostic Tools: Use a scan tool to check for any DTCs related to the MAP sensor.

- Pressure Testing: Use a vacuum gauge or a pressure tester to verify the MAP sensor’s reading against the actual manifold pressure.

- Replacement: If the MAP sensor is found to be faulty, it needs to be replaced with a new one.

FAQs about the MAP Sensor

Q: What is the difference between a MAP sensor and a MAF sensor?

A: The MAP sensor measures manifold absolute pressure, while the Mass Air Flow (MAF) sensor measures the mass of air entering the engine. Both sensors are crucial for engine control, but they provide different types of information. The MAP sensor measures the amount of air already in the manifold, while the MAF sensor measures the amount of air flowing into the engine.

Q: How often should the MAP sensor be replaced?

A: The MAP sensor is typically a durable component and does not require frequent replacement. However, it’s essential to inspect the sensor for signs of wear or damage during routine maintenance.

Q: Can I clean a MAP sensor?

A: While cleaning a MAP sensor is possible, it is not recommended. The sensor is a delicate electronic component, and cleaning it incorrectly can damage it. It’s best to replace a faulty MAP sensor with a new one.

Q: Can I drive with a faulty MAP sensor?

A: Driving with a faulty MAP sensor can lead to various problems, including poor engine performance, increased fuel consumption, and emissions issues. It’s best to address a faulty MAP sensor promptly to avoid further complications.

Tips for Maintaining the MAP Sensor

- Regular Maintenance: As part of routine engine maintenance, inspect the MAP sensor for any signs of wear or damage.

- Avoid Contaminants: Keep the MAP sensor clean and free from dirt, oil, or other contaminants.

- Use High-Quality Fuel: Using high-quality fuel can help prevent the buildup of deposits in the intake manifold, which can affect the MAP sensor’s performance.

- Professional Inspection: If you suspect a problem with the MAP sensor, consult a qualified mechanic for diagnosis and repair.

Conclusion

The manifold absolute pressure sensor is a critical component in modern internal combustion engines. It plays a crucial role in regulating fuel delivery, ignition timing, and emissions control. Understanding the MAP sensor’s operation, importance, and potential issues is essential for maintaining optimal engine performance, fuel efficiency, and emissions compliance. By taking appropriate steps to ensure the proper functioning of the MAP sensor, vehicle owners can maximize their vehicle’s performance and longevity.

Closure

Thus, we hope this article has provided valuable insights into The Crucial Role of the Manifold Absolute Pressure Sensor in Engine Performance. We thank you for taking the time to read this article. See you in our next article!