The Crucial Role of the Manifold Absolute Pressure Sensor in Isuzu D-Max Vehicles

Related Articles: The Crucial Role of the Manifold Absolute Pressure Sensor in Isuzu D-Max Vehicles

Introduction

With great pleasure, we will explore the intriguing topic related to The Crucial Role of the Manifold Absolute Pressure Sensor in Isuzu D-Max Vehicles. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Crucial Role of the Manifold Absolute Pressure Sensor in Isuzu D-Max Vehicles

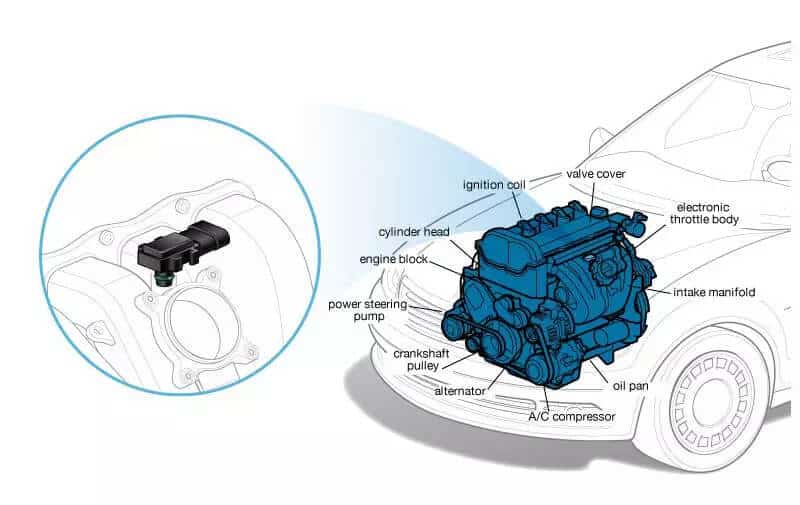

The Isuzu D-Max, a popular pickup truck known for its ruggedness and reliability, relies on a sophisticated engine management system to optimize performance and fuel efficiency. One of the key components in this system is the Manifold Absolute Pressure (MAP) sensor, a small but vital device that plays a critical role in determining the engine’s operating conditions.

Understanding the MAP Sensor’s Function

The MAP sensor is responsible for measuring the pressure within the engine’s intake manifold. This pressure, known as manifold absolute pressure (MAP), is a direct indicator of the amount of air being drawn into the engine. The sensor converts this pressure into an electrical signal that is sent to the engine control unit (ECU).

How the MAP Sensor Works

The MAP sensor typically employs a diaphragm-based design. A flexible diaphragm separates two chambers within the sensor. One chamber is exposed to the intake manifold pressure, while the other is sealed and maintained at a reference pressure. As the intake manifold pressure changes, the diaphragm flexes, altering the resistance of a strain gauge. This change in resistance is translated into an electrical signal, which is proportional to the intake manifold pressure.

The MAP Sensor’s Significance in Engine Management

The information provided by the MAP sensor is crucial for the ECU to make accurate adjustments to various engine parameters. This includes:

- Fuel Injection Timing: The ECU uses the MAP sensor data to determine the optimal timing for fuel injection. Higher intake manifold pressure indicates a greater volume of air entering the cylinders, requiring more fuel to maintain the correct air-fuel ratio.

- Ignition Timing: The MAP sensor also helps the ECU adjust ignition timing. Higher intake manifold pressure often corresponds to higher engine load, necessitating adjustments to ignition timing for optimal combustion.

- Air-Fuel Ratio Control: The ECU uses the MAP sensor data in conjunction with other sensors, such as the oxygen sensor, to precisely control the air-fuel ratio. This ensures efficient combustion and minimizes emissions.

- Boost Control (Turbocharged Engines): In turbocharged D-Max models, the MAP sensor provides crucial information for the ECU to manage boost pressure. The ECU uses this data to regulate the turbocharger’s operation, ensuring optimal performance and preventing overboost.

Common Symptoms of a Faulty MAP Sensor

A malfunctioning MAP sensor can lead to various engine issues, including:

- Poor Engine Performance: The engine may experience reduced power, hesitation, or rough idling.

- Increased Fuel Consumption: An inaccurate reading from the MAP sensor can lead to inefficient fuel delivery, resulting in higher fuel consumption.

- Engine Misfire: Incorrect fuel-air mixture due to a faulty MAP sensor can cause engine misfires.

- Check Engine Light: The ECU will typically illuminate the check engine light if it detects a problem with the MAP sensor.

Diagnosing a Faulty MAP Sensor

Diagnosing a faulty MAP sensor often involves a combination of steps:

- Visual Inspection: Check the sensor for any visible damage, such as cracks, loose connections, or corrosion.

- Check Engine Light Codes: Use an OBD-II scanner to read any error codes related to the MAP sensor.

- Pressure Testing: A qualified mechanic can use a pressure gauge to test the actual pressure in the intake manifold and compare it to the readings from the MAP sensor.

- Signal Testing: A multimeter can be used to test the electrical signal output from the MAP sensor.

Replacing a Faulty MAP Sensor

Replacing a faulty MAP sensor is a relatively straightforward procedure that can usually be performed by a skilled DIY enthusiast. However, it’s essential to follow the manufacturer’s instructions and use genuine parts to ensure proper operation and safety.

FAQs

Q: How often should I replace the MAP sensor in my D-Max?

A: The MAP sensor is typically a long-lasting component. However, it’s recommended to have it inspected during routine maintenance intervals or if you experience any of the symptoms mentioned above.

Q: Can I clean the MAP sensor to improve its performance?

A: While some sensors may benefit from cleaning, it’s generally not recommended for MAP sensors. Cleaning can damage the delicate components and potentially lead to further issues.

Q: What are the potential consequences of ignoring a faulty MAP sensor?

A: Ignoring a faulty MAP sensor can result in poor engine performance, increased fuel consumption, and even engine damage in the long run.

Tips

- Regular Maintenance: Adhering to the recommended maintenance schedule for your D-Max can help prevent premature sensor failure.

- Quality Parts: Always use genuine or high-quality aftermarket parts when replacing the MAP sensor.

- Professional Diagnosis: If you suspect a faulty MAP sensor, it’s best to consult a qualified mechanic for proper diagnosis and repair.

Conclusion

The MAP sensor plays a crucial role in ensuring optimal performance, fuel efficiency, and emissions control in the Isuzu D-Max. Understanding its function and the potential consequences of a malfunction is essential for maintaining the vehicle’s reliability and longevity. Regular maintenance, prompt diagnosis, and timely replacement of any faulty sensors are key to ensuring a smooth and trouble-free driving experience.

Closure

Thus, we hope this article has provided valuable insights into The Crucial Role of the Manifold Absolute Pressure Sensor in Isuzu D-Max Vehicles. We appreciate your attention to our article. See you in our next article!