The Unsung Hero of Engine Control: Delving into the Map Sensor Connector

Related Articles: The Unsung Hero of Engine Control: Delving into the Map Sensor Connector

Introduction

With great pleasure, we will explore the intriguing topic related to The Unsung Hero of Engine Control: Delving into the Map Sensor Connector. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Unsung Hero of Engine Control: Delving into the Map Sensor Connector

The intricate dance of modern combustion engines is orchestrated by a complex symphony of sensors and actuators. Among these crucial components, the manifold absolute pressure (MAP) sensor connector plays a vital role in ensuring smooth and efficient engine operation. This seemingly unassuming connector serves as the bridge between the MAP sensor, a key player in engine management, and the engine control unit (ECU).

Understanding the MAP Sensor and its Importance

The MAP sensor, a vital component in modern fuel-injected engines, measures the absolute pressure within the engine’s intake manifold. This pressure, a direct indicator of the amount of air entering the cylinders, is crucial for determining the appropriate fuel-air mixture for optimal combustion. The ECU relies heavily on the MAP sensor’s data to calculate the precise amount of fuel to inject into the cylinders, ensuring efficient combustion and reducing harmful emissions.

The Role of the MAP Sensor Connector

The MAP sensor connector acts as the vital link between the MAP sensor and the ECU. This connector, typically a multi-pin electrical connector, transmits the pressure readings from the MAP sensor to the ECU. The connector’s primary function is to provide a secure and reliable electrical connection, ensuring that the MAP sensor’s data reaches the ECU accurately and without interruption.

Types of MAP Sensor Connectors

MAP sensor connectors are available in various designs, each tailored to specific applications and vehicle models. Common types include:

- Standard Connector: This type features a simple, robust design with a specific number of pins, often two or three, to accommodate the signal and ground wires from the MAP sensor.

- Sealed Connector: These connectors, often used in harsh environments, feature a protective seal to prevent moisture, dirt, and debris from entering and disrupting the electrical connection.

- Modular Connector: This type allows for customization, enabling manufacturers to adapt the connector to specific vehicle designs and wiring configurations.

The Importance of a Properly Functioning MAP Sensor Connector

A faulty MAP sensor connector can lead to a range of engine problems, including:

- Engine Misfire: An inaccurate pressure reading due to a faulty connector can lead to an incorrect fuel-air mixture, causing misfires and engine performance issues.

- Rough Idle: A faulty connector can disrupt the signal from the MAP sensor, resulting in an erratic idle speed and engine instability.

- Increased Fuel Consumption: An incorrect fuel-air mixture due to a faulty connector can lead to inefficient combustion, resulting in increased fuel consumption.

- Check Engine Light (CEL): The ECU, detecting an issue with the MAP sensor signal, will illuminate the CEL, indicating a potential problem that requires attention.

Diagnosing Issues with the MAP Sensor Connector

Identifying problems with the MAP sensor connector requires a systematic approach:

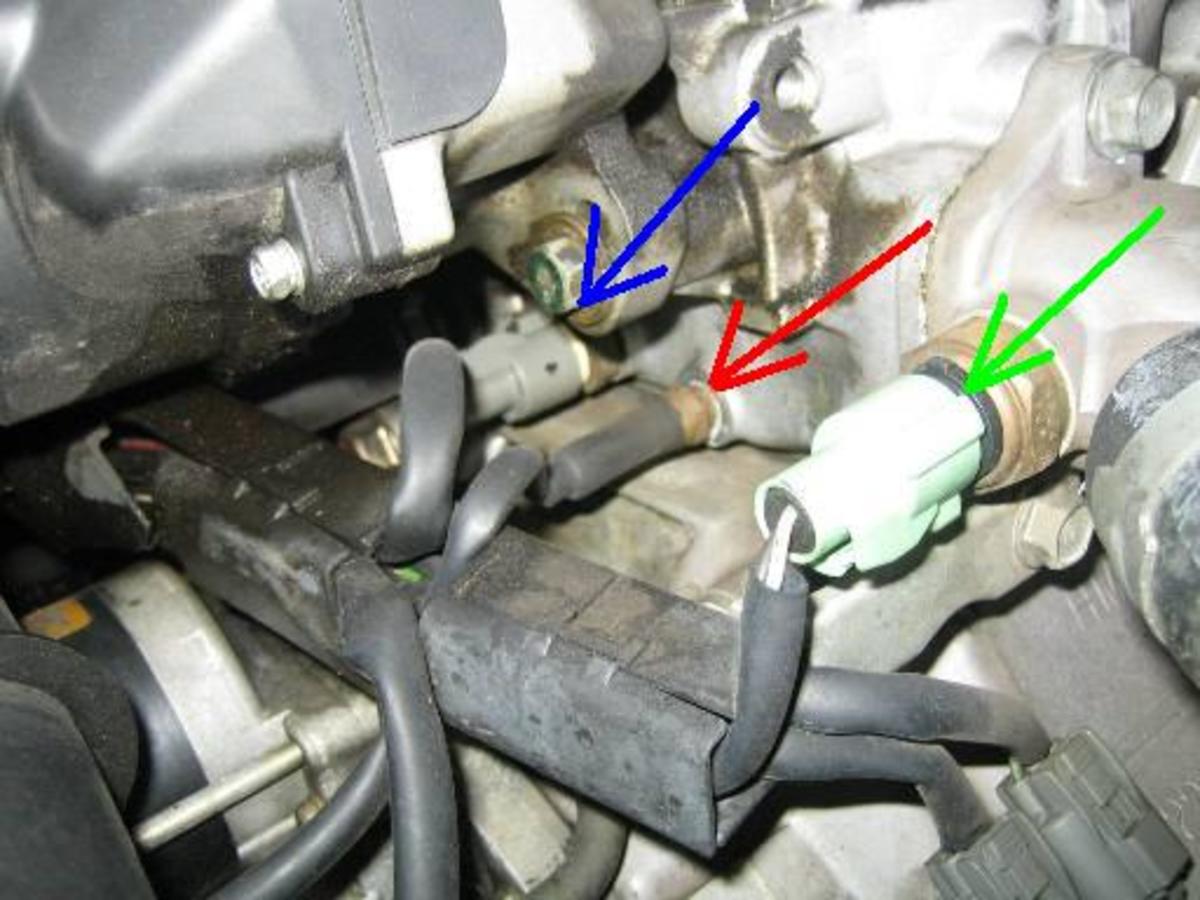

- Visual Inspection: Inspect the connector for signs of damage, corrosion, or loose connections.

- Electrical Testing: Use a multimeter to check the voltage and resistance at the connector pins, comparing them to the manufacturer’s specifications.

- Pressure Testing: Apply a known pressure to the MAP sensor and verify that the ECU receives the correct readings.

Tips for Maintaining the MAP Sensor Connector

Regular maintenance of the MAP sensor connector can help prevent issues and ensure optimal engine performance:

- Clean the Connector: Periodically clean the connector pins with a contact cleaner to remove any dirt or debris that could interfere with the electrical connection.

- Inspect for Damage: Regularly inspect the connector for signs of wear and tear, and replace it if necessary.

- Ensure Secure Connection: Ensure that the connector is securely fastened to both the MAP sensor and the ECU wiring harness.

FAQs about the MAP Sensor Connector

Q: What are the symptoms of a faulty MAP sensor connector?

A: Symptoms of a faulty MAP sensor connector can include engine misfire, rough idle, increased fuel consumption, and illumination of the check engine light.

Q: How can I test the MAP sensor connector?

A: You can test the MAP sensor connector by visually inspecting it for damage, using a multimeter to check the voltage and resistance at the connector pins, and applying a known pressure to the MAP sensor and verifying that the ECU receives the correct readings.

Q: How often should I clean the MAP sensor connector?

A: It is recommended to clean the MAP sensor connector at least once a year or more frequently if the vehicle is exposed to harsh environments.

Q: Can I replace the MAP sensor connector myself?

A: Replacing the MAP sensor connector can be a straightforward process for some individuals with basic mechanical skills. However, it is always recommended to consult with a qualified mechanic if you are unsure about the procedure.

Conclusion

The MAP sensor connector, though seemingly insignificant, plays a critical role in ensuring smooth and efficient engine operation. Its importance lies in its ability to provide a reliable electrical connection between the MAP sensor and the ECU, allowing the engine control system to function accurately and efficiently. Recognizing the importance of this connector and implementing proper maintenance practices can help prevent engine issues and ensure optimal performance.

Closure

Thus, we hope this article has provided valuable insights into The Unsung Hero of Engine Control: Delving into the Map Sensor Connector. We appreciate your attention to our article. See you in our next article!