The Vital Role of the Manifold Absolute Pressure Sensor Bracket in Automotive Systems

Related Articles: The Vital Role of the Manifold Absolute Pressure Sensor Bracket in Automotive Systems

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to The Vital Role of the Manifold Absolute Pressure Sensor Bracket in Automotive Systems. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

The Vital Role of the Manifold Absolute Pressure Sensor Bracket in Automotive Systems

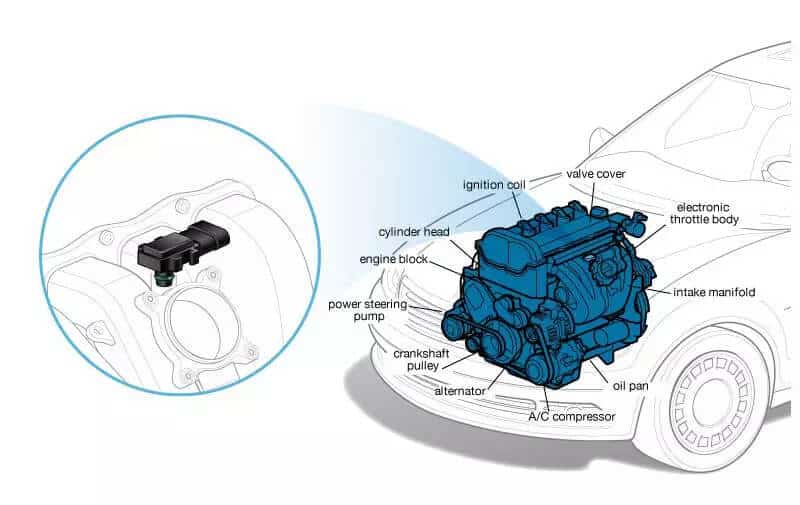

The manifold absolute pressure (MAP) sensor, a crucial component in modern automotive engines, plays a vital role in determining engine load and regulating fuel delivery. This sensor, often housed within a dedicated bracket, measures the pressure within the engine’s intake manifold, providing valuable data to the engine control unit (ECU) for precise fuel-air mixture control. This article delves into the intricacies of the MAP sensor bracket, exploring its design, functionality, and significance in ensuring optimal engine performance.

Understanding the MAP Sensor Bracket’s Purpose

The MAP sensor bracket serves as a robust foundation for the MAP sensor, securely anchoring it within the engine bay. This strategic placement ensures the sensor is positioned in close proximity to the intake manifold, allowing for accurate pressure readings. The bracket’s design often incorporates features that protect the sensor from environmental factors such as heat, vibrations, and potential damage.

Design and Construction of the MAP Sensor Bracket

The MAP sensor bracket is typically constructed from durable materials like steel or aluminum, chosen for their resistance to corrosion and mechanical stress. The bracket’s design varies depending on the specific vehicle model and engine configuration. However, common features include:

- Mounting Points: The bracket features precise mounting points that align with the engine’s mounting points, ensuring a secure and stable fit.

- Sensor Housing: The bracket often incorporates a housing specifically designed to accommodate the MAP sensor, providing protection and proper alignment.

- Integrated Connectors: Some brackets integrate electrical connectors for the MAP sensor, simplifying wiring and ensuring a secure connection.

Function and Importance of the MAP Sensor Bracket

The MAP sensor bracket’s primary function is to provide a stable and reliable mounting platform for the MAP sensor. This secure mounting is crucial for several reasons:

- Accurate Pressure Readings: A secure bracket ensures the MAP sensor is positioned correctly in relation to the intake manifold, enabling accurate pressure measurements. Inaccurate pressure readings can lead to poor fuel-air mixture, affecting engine performance, fuel economy, and emissions.

- Protection from Environmental Factors: The bracket shields the sensor from external influences such as heat, vibration, and potential damage. This protection ensures the sensor’s longevity and reliability.

- Simplified Installation and Maintenance: The bracket simplifies the installation and maintenance of the MAP sensor, facilitating quick and efficient access for inspection and replacement.

Potential Issues with the MAP Sensor Bracket

While the MAP sensor bracket is designed for durability, it can be susceptible to wear and tear over time. Potential issues include:

- Corrosion: Exposure to elements like salt, moisture, and road grime can lead to corrosion, weakening the bracket’s structural integrity.

- Cracks or Breaks: Extreme vibrations or impact can cause cracks or breaks in the bracket, compromising the sensor’s secure mounting.

- Loose Mounting: Over time, the bracket’s mounting points can loosen, leading to instability and inaccurate pressure readings.

Troubleshooting and Diagnosis

If you suspect issues with the MAP sensor bracket, a thorough inspection is crucial. Here are some steps to help diagnose potential problems:

- Visual Inspection: Examine the bracket for any signs of corrosion, cracks, or breaks.

- Check for Loose Connections: Ensure the MAP sensor is securely mounted to the bracket and that all electrical connections are tight.

- Test the MAP Sensor: Use a diagnostic scanner to check the MAP sensor’s readings and compare them to the manufacturer’s specifications.

Replacing the MAP Sensor Bracket

If the MAP sensor bracket is damaged or compromised, replacement is necessary. The process typically involves:

- Disconnecting the MAP Sensor: Disconnect the electrical connector and remove the sensor from the bracket.

- Removing the Bracket: Remove the bracket from the engine bay using appropriate tools.

- Installing the New Bracket: Install the new bracket securely, ensuring all mounting points are properly aligned.

- Reconnecting the Sensor: Reinstall the MAP sensor and reconnect the electrical connector.

FAQs about the MAP Sensor Bracket

Q: How often should I inspect the MAP sensor bracket?

A: Regular inspections are recommended, especially in environments with harsh weather conditions. A visual inspection during routine maintenance is sufficient.

Q: Can I repair a damaged MAP sensor bracket?

A: Repairing a damaged MAP sensor bracket is not recommended. A compromised bracket can compromise the sensor’s accuracy and security. Replacing the bracket is the most reliable solution.

Q: What are the symptoms of a faulty MAP sensor bracket?

A: Symptoms of a faulty bracket can include rough idle, poor acceleration, increased fuel consumption, and engine misfires.

Q: Is it possible to drive with a damaged MAP sensor bracket?

A: It is not advisable to drive with a damaged MAP sensor bracket. The sensor’s position and stability are critical for accurate engine operation.

Tips for Maintaining the MAP Sensor Bracket

- Regular Cleaning: Clean the bracket and surrounding area during routine maintenance to remove dirt, grime, and potential corrosive substances.

- Check for Loose Connections: Periodically inspect the bracket’s mounting points and electrical connections to ensure they are secure.

- Avoid Extreme Stress: Minimize exposure to extreme vibrations or impact that could damage the bracket.

Conclusion

The MAP sensor bracket plays a vital role in ensuring accurate engine performance by providing a secure and reliable mounting platform for the MAP sensor. Its design and construction contribute to the sensor’s stability, protection, and overall functionality. Recognizing the importance of the MAP sensor bracket and performing regular inspections and maintenance ensures optimal engine operation, fuel efficiency, and emissions control.

Closure

Thus, we hope this article has provided valuable insights into The Vital Role of the Manifold Absolute Pressure Sensor Bracket in Automotive Systems. We appreciate your attention to our article. See you in our next article!