Understanding and Utilizing MAP Sensor Extensions: A Comprehensive Guide

Related Articles: Understanding and Utilizing MAP Sensor Extensions: A Comprehensive Guide

Introduction

In this auspicious occasion, we are delighted to delve into the intriguing topic related to Understanding and Utilizing MAP Sensor Extensions: A Comprehensive Guide. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Understanding and Utilizing MAP Sensor Extensions: A Comprehensive Guide

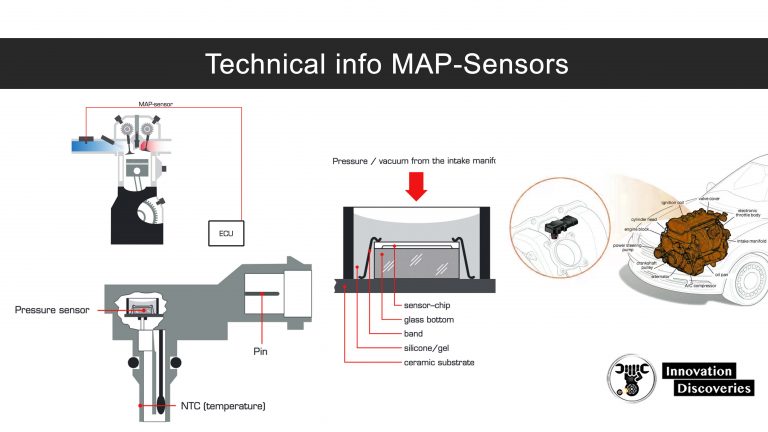

The manifold absolute pressure (MAP) sensor is a crucial component in modern internal combustion engines, playing a vital role in determining engine load and adjusting fuel injection and ignition timing. However, in certain scenarios, the MAP sensor’s location can pose challenges for accurate readings and optimal engine performance. This is where MAP sensor extensions come into play, providing a solution to overcome these limitations and enhance engine efficiency.

The Significance of MAP Sensor Placement

The MAP sensor is typically situated in the intake manifold, directly measuring the pressure within the manifold. This pressure, also known as manifold vacuum, provides a direct indication of engine load. When the engine is under high load, the manifold pressure increases, indicating a greater demand for fuel and air. Conversely, low manifold pressure signals a lighter load.

However, the physical location of the MAP sensor can sometimes lead to inaccuracies in pressure readings. This can occur due to:

- Interference: The sensor’s proximity to other components, such as the throttle body or air intake, can cause obstructions or turbulence in the airflow, affecting pressure readings.

- Heat: The engine bay environment can subject the MAP sensor to high temperatures, potentially affecting its sensitivity and accuracy.

- Vibration: The constant vibration of the engine can disrupt the sensor’s ability to provide precise readings, particularly in high-performance applications.

The Role of MAP Sensor Extensions

MAP sensor extensions address these challenges by physically relocating the sensor to a more advantageous position. These extensions typically consist of a hose or tube that connects the sensor to the intake manifold, allowing the sensor to be placed in a location that minimizes interference, heat, and vibration.

Benefits of Using MAP Sensor Extensions

Employing MAP sensor extensions offers several advantages, contributing to improved engine performance and overall efficiency:

- Enhanced Accuracy: By removing the sensor from potentially disruptive environments, extensions ensure more accurate pressure readings, leading to more precise fuel and ignition timing adjustments.

- Improved Reliability: Shielding the sensor from extreme heat and vibrations enhances its longevity and reliability, reducing the risk of sensor failure.

- Greater Flexibility: Extensions provide flexibility in sensor placement, allowing for optimal positioning based on specific vehicle configurations and engine modifications.

- Easier Access: Relocating the sensor to a more accessible area simplifies maintenance and troubleshooting, facilitating sensor replacement or inspection.

Types of MAP Sensor Extensions

MAP sensor extensions come in various configurations, tailored to different applications and needs:

- Hose Extensions: These extensions consist of a flexible hose, typically made of silicone or nylon, connecting the sensor to the manifold. Hose extensions are often used for minor repositioning and offer good flexibility.

- Tube Extensions: Tube extensions employ a rigid tube, usually made of metal or plastic, providing a more robust and durable solution for significant relocation.

- Custom-Made Extensions: For highly specific applications or custom engine builds, specialized extensions can be fabricated to meet precise requirements.

Considerations When Choosing a MAP Sensor Extension

When selecting a MAP sensor extension, several factors should be considered:

- Material Compatibility: Ensure the extension material is compatible with the sensor and the intake manifold to prevent corrosion or leaks.

- Length and Diameter: Choose an extension with the appropriate length and diameter to ensure proper airflow and pressure readings.

- Durability: Select an extension made of durable materials that can withstand the harsh environment of the engine bay.

- Installation: Consider the ease of installation and the availability of mounting points for the extension.

FAQs Regarding MAP Sensor Extensions

1. Are MAP sensor extensions necessary for all vehicles?

MAP sensor extensions are not universally required. However, they can be beneficial in specific scenarios, such as vehicles with modified intake manifolds, high-performance engines, or those experiencing sensor-related issues.

2. Can I install a MAP sensor extension myself?

While installing a MAP sensor extension is generally straightforward, it requires some mechanical aptitude and familiarity with automotive systems. If you are unsure, it is recommended to seek professional assistance.

3. What are the potential risks associated with using MAP sensor extensions?

Improper installation or the use of incompatible materials can lead to leaks, inaccurate pressure readings, and potential damage to the sensor or engine.

4. How do I know if my MAP sensor needs an extension?

Symptoms of a faulty or poorly positioned MAP sensor can include poor fuel economy, rough idling, hesitation during acceleration, or engine misfires. If you suspect a problem with your MAP sensor, it is advisable to consult a qualified mechanic.

5. Can I use a MAP sensor extension on a turbocharged engine?

Yes, MAP sensor extensions can be used on turbocharged engines. However, it is essential to select an extension specifically designed for turbocharged applications, as it needs to withstand higher pressure and temperatures.

Tips for Using MAP Sensor Extensions

- Inspect the extension regularly: Check for leaks, cracks, or damage to ensure proper functionality.

- Use quality materials: Opt for extensions made from durable and compatible materials to prevent premature failure.

- Secure the extension properly: Ensure the extension is securely mounted to avoid movement or disconnection.

- Seek professional assistance if needed: If you are unsure about installation or troubleshooting, consult a qualified mechanic.

Conclusion

MAP sensor extensions offer a valuable solution for optimizing engine performance by addressing potential limitations related to sensor placement. By providing a more accurate and reliable pressure reading, extensions contribute to improved fuel economy, smoother engine operation, and enhanced overall efficiency. While not always necessary, in specific scenarios, MAP sensor extensions can be crucial for achieving optimal engine performance and extending the life of the MAP sensor. However, it is essential to carefully consider the factors involved in choosing and installing an extension to ensure proper functionality and avoid potential complications.

Closure

Thus, we hope this article has provided valuable insights into Understanding and Utilizing MAP Sensor Extensions: A Comprehensive Guide. We thank you for taking the time to read this article. See you in our next article!