Understanding the Crucial Role of the MAP Sensor in Duramax Engines

Related Articles: Understanding the Crucial Role of the MAP Sensor in Duramax Engines

Introduction

With enthusiasm, let’s navigate through the intriguing topic related to Understanding the Crucial Role of the MAP Sensor in Duramax Engines. Let’s weave interesting information and offer fresh perspectives to the readers.

Table of Content

Understanding the Crucial Role of the MAP Sensor in Duramax Engines

The Duramax engine, a powerhouse known for its durability and performance, relies on a complex network of sensors to ensure optimal operation. Among these sensors, the Manifold Absolute Pressure (MAP) sensor plays a pivotal role in regulating engine performance and fuel efficiency.

The Role of the MAP Sensor

The MAP sensor acts as a crucial link between the engine’s intake manifold and the engine control unit (ECU). It measures the absolute pressure within the intake manifold, providing the ECU with essential data to calculate the amount of air entering the engine. This information is vital for:

- Fuel Injection Control: The ECU utilizes the MAP sensor readings to determine the appropriate amount of fuel to inject into the cylinders. Accurate air-to-fuel ratios are essential for optimal combustion and engine performance.

- Ignition Timing: The MAP sensor data also helps the ECU adjust ignition timing for optimal combustion. Precise ignition timing ensures efficient fuel burning and prevents premature detonation, which can damage the engine.

- Boost Control (for Turbocharged Engines): In turbocharged Duramax engines, the MAP sensor plays a crucial role in regulating boost pressure. The ECU uses the sensor readings to control the wastegate, which manages exhaust gas flow to maintain optimal boost levels.

How the MAP Sensor Works

The MAP sensor typically uses a piezoresistive element, which changes its resistance based on the applied pressure. When air enters the intake manifold, it creates pressure that acts upon the sensor’s element. The ECU interprets the change in resistance as a pressure reading, allowing it to calculate the amount of air entering the engine.

Signs of a Faulty MAP Sensor

A malfunctioning MAP sensor can lead to various engine issues, including:

- Rough Idle: An inaccurate air pressure reading can cause the ECU to miscalculate fuel injection, resulting in a rough idle.

- Poor Acceleration: A faulty sensor can lead to inconsistent fuel-air mixtures, resulting in sluggish acceleration and reduced power.

- Engine Stalling: In extreme cases, a malfunctioning MAP sensor can lead to the engine stalling, especially at low speeds or idle.

- Check Engine Light: A faulty MAP sensor will trigger the Check Engine Light, indicating a problem that requires attention.

Diagnosing and Replacing a MAP Sensor

Diagnosing a faulty MAP sensor typically involves:

- Visual Inspection: Checking for any physical damage, loose connections, or signs of corrosion on the sensor.

- Using a Scan Tool: A scan tool can read diagnostic trouble codes (DTCs) related to the MAP sensor.

- Performing a Pressure Test: A pressure test can verify if the sensor is providing accurate pressure readings.

Replacing a faulty MAP sensor is generally straightforward:

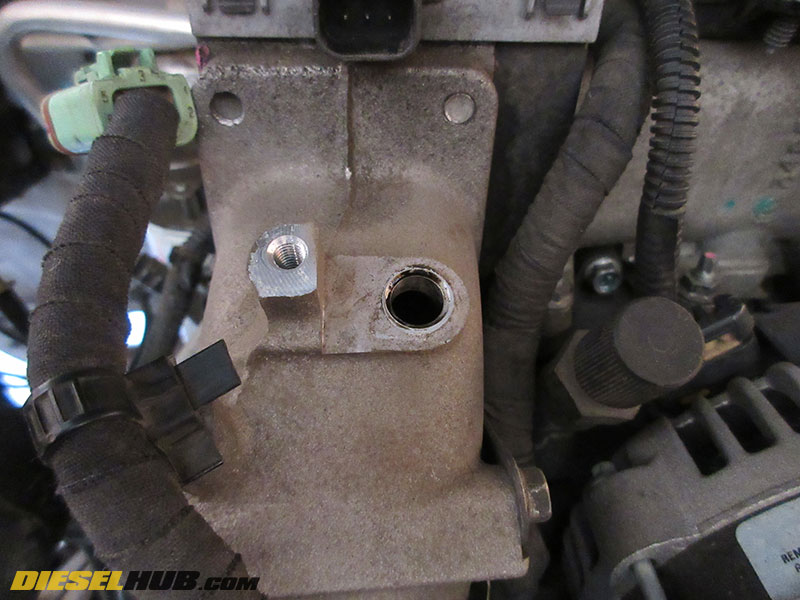

- Locate the sensor: The MAP sensor is typically located on the intake manifold, close to the throttle body.

- Disconnect the electrical connector: Disconnect the electrical connector leading to the sensor.

- Remove the sensor: Unscrew the sensor from the intake manifold.

- Install the new sensor: Install the new sensor in the same location, ensuring a secure connection.

- Reconnect the electrical connector: Reconnect the electrical connector to the new sensor.

Frequently Asked Questions (FAQs)

Q: How often should I replace my MAP sensor?

A: The MAP sensor is a durable component and doesn’t typically require regular replacement. However, it can become faulty due to age, environmental conditions, or physical damage. If you experience any of the symptoms mentioned above, it’s advisable to inspect and potentially replace the sensor.

Q: Can I clean my MAP sensor?

A: It is not recommended to clean the MAP sensor. Cleaning can damage the sensor’s delicate internal components, potentially leading to further problems.

Q: Can I use a generic MAP sensor for my Duramax engine?

A: It is crucial to use a MAP sensor specifically designed for your Duramax engine model and year. Using a generic sensor can lead to compatibility issues and affect engine performance.

Tips for Maintaining Your MAP Sensor

- Regular Maintenance: As part of regular engine maintenance, visually inspect the MAP sensor for any damage or signs of corrosion.

- Avoid Excessive Dust and Dirt: Keep the engine bay clean to prevent dust and dirt from accumulating on the sensor.

- Proper Electrical Connections: Ensure all electrical connections to the sensor are secure and free from corrosion.

Conclusion

The MAP sensor plays a vital role in ensuring optimal performance and fuel efficiency of Duramax engines. Understanding its function and potential issues can help owners identify problems early and maintain their engine’s health. By following the tips and taking appropriate action when necessary, you can ensure your Duramax engine continues to deliver its renowned power and reliability.

Closure

Thus, we hope this article has provided valuable insights into Understanding the Crucial Role of the MAP Sensor in Duramax Engines. We appreciate your attention to our article. See you in our next article!